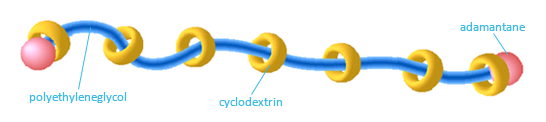

Basic components of Slide-Ring Material: molecular necklace

Structure and functions of Slide-Ring Material: pulley effect and sliding effect

Free movement of cross-linking points (pulley effect)

Excellent elasticity … Returns to original form even after being squeezed … Difficult to break even when pulled

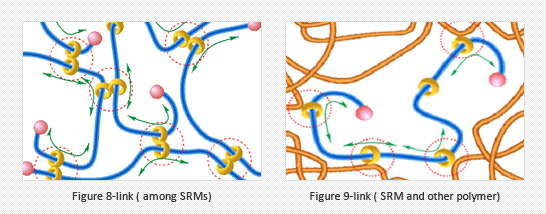

At Prof. Kohzo Ito’s laboratory at The University of Tokyo, the amount of clathrate in the cyclic molecules (cyclodextrin) of a molecular necklace (polyrotaxane) was controlled and given free movement in a linear polymer, thereby cross-linking bonded cyclic molecules. Cyclodextrin, a component of Slide-Ring Material, has a large number of hydroxyl groups. Taking this as a cross-linking point, cross-linking the bonded molecular necklaces or molecular necklaces with other polymers enables free movement of cross-linking points to build supramolecular networks. This is the basic structure of Slide-Ring Material. Cross-linking points are used for a pulley effect, equalizing the tensions among polymers. Thanks to this effect, Slide-Ring Material has unique mechanical properties and has been able to form a polymeric material with completely new functions.

Sliding effect

Features of Slide-Ring Material

1. Unique mechanical properties

The stress elongation property of Slide-Ring Material due to its pulley effect displays different behavior from that of traditional polymeric materials, a “convex” curve (J-type stress elongation curve) in the low elongation regions, and also shows “no hysteresis”. Stress elongation properties such as these are described as being mechanical properties that are close to biological tissue such as skin, muscles and blood vessels, etc.

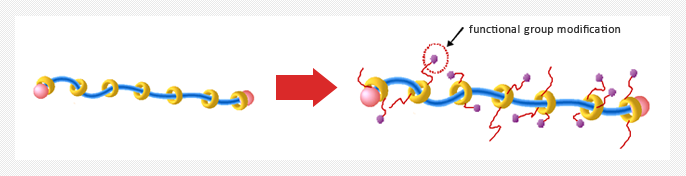

2. Control of physical properties by means of chemical modification

By chemically modifying the hydroxyl group of cyclodextrin, Slide-Ring Material will enable control of the following kinds of abilities at the molecular level.

・Solubility in solvents

・Compatibility with other materials

・Phase transition temperature

・Special functions (temperature response, rheology)

・Hydrophilicity, hydrophobicity

・Reactivity (heat/light)

・Dispersivity (emulsification)

These properties make it possible to combine Slide-Ring Material with other generic polymeric materials, and the properties of Slide-Ring Material can be transferred and added to the properties of these materials.

3. Biological safety

Polyethyleneglycol, a component of Slide-Ring Material, is widely used in pharmaceuticals and cosmetics, etc. Likewise, cyclodextrin is also used extensively in pharmaceuticals and foods, etc.

In previous cytotoxicity and muscle enthesis trials using Slide-Ring Material, there was no inflammatory response in relation to the enthesis structure area, nor was there any visible adhesion of materials and structure.

References concerning Slide-Ring Material

There have already been many papers published concerning Slide-Ring Material. In addition, please refer to the following detailed sources of information.

- Slide-Ring Material reference information: Supramolecules using macromolecules and cyclic molecules / Research of slide-ring polymeric material